Difference between revisions of "Artificial reefs"

| Line 14: | Line 14: | ||

| + | |||

| + | ===Reef units=== | ||

[[Image:ArtificialReefUnits.jpg|thumb|right|250px|Figure 1: Examples of different reef units]] | [[Image:ArtificialReefUnits.jpg|thumb|right|250px|Figure 1: Examples of different reef units]] | ||

| − | + | Reef units of different shapes and constructive characteristics can also be used to construct ARs. Particularly in Japan (O’Leary, 2001<ref name="OL">O’Leary, Hubbard T., O’Leary D. Artificial Reefs Feasibility Study, Coastal Resources Centre National University of Ireland Cork, 2001</ref>) these units have a huge popularity and their development is growing. Their macro-roughness induces the dumping of the incident wave agitation above the reef, creating local turbulence and vortices. Usually they are made by steel, reinforced or pre-stressed concrete, fibreglass or a variety of composite materials. These units are produced individually on shore and transported to the staging area. Here they could be combined in a variety of configurations thus allowing adjustment to local conditions and needs. Most of the units are designed to provide nursery areas for fish, to permit a good water recirculation, promote current deflections and marine colonization (O’Leary, 2001<ref name="OL"/>). It is very difficult to provide a catalogue of all shapes and materials employed to realize reef units, because the variety of them is huge. Although, some examples are shown in Figure 1. </br> | |

| − | Reef units of different shapes and constructive characteristics can also be used to construct ARs. Particularly in Japan (O’Leary, 2001<ref name="OL">O’Leary, Hubbard T., O’Leary D. Artificial Reefs Feasibility Study, Coastal Resources Centre National University of Ireland Cork, 2001</ref>) these units have a huge popularity and their development is growing. Their macro-roughness induces the dumping of the incident wave agitation above the reef, creating local turbulence and vortices. Usually they are made by steel, reinforced or pre-stressed concrete, fibreglass or a variety of composite materials. These units are produced individually on shore and transported to the staging area. Here they could be combined in a variety of configurations thus allowing adjustment to local conditions and needs. Most of the units are designed to provide nursery areas for fish, to permit a good water recirculation, promote current deflections and marine colonization (O’Leary, 2001<ref name="OL"/>). It is very difficult to provide a catalogue of all shapes and materials employed to realize reef units, because the variety of them is | + | |

| − | huge. Although, some examples are shown in Figure 1. | + | |

| + | Figure 1.e shows an interesting sample of reef units, the so-called tecnoreef modules. Constructed from concrete-based natural products, they pose little impact on the ecosystem. Each module consists of reinforced octagonal plates, which are characterized by holes (usually four) having a quarter of a circle shape. The modules are assembled together to create a sort of pyramid that usually consists of | ||

| + | three octagonal plates, the so called “base system”. Generally, the structure basis is always larger than the crest and thus the resistance and stability to cross-shore currents and drag forces are ensured. The modules tend to globally reduce cross-shore currents due to friction and turbulence, with consequent deposition within the pyramids and around them of transported sediments. That is increased by the differently inclined facets on the external and | ||

| + | internal surfaces of the modules. These geometric irregularities act as accelerators for localized microcurrents, and create within each element continuous circular currents (spheres of water) which release their energy upwards. Due to these localized variations, the structure ensures a constant circulation and exchange of water, causing the influx of nutrients and permanent occupation by flora and fauna. <br/> | ||

| + | |||

| + | |||

| + | Figure 7.f shows the reef ball elements. These have an hemispherical shape (Harris, 1995) and are typically 1-2 m high and 2 m wide. A reef ball is made by polyester with glass reinforcement and is thus very resistant to corrosion. It’s characterised by high porosity (40-50%), roughness and many cavities or holes: | ||

| + | * that assure a quick colonisations by marine species and aquatic plants (Pilarczyk, 2003a). The increase of structure complexity and consequent increase of induced biodiversity can be improved by roughening the inner and outer surfaces (Pilarczyk, 2003a). | ||

| + | * that generate turbulence and consequently production of vortices and vertical jets; usually, the hole sizes are specifically designed to increase energy dissipation. The reef ball contains a buoy that allows it to float during construction phase and that is deflated when the element is definitively placed. Another important function of the reef ball is to increase the colonization by marine species, i.e. animals and plants (Pilarczyk, 2003a). Under storm attacks, the geometry of reef balls reduces its stability whereas its porosity, through the reduction of lifting forces, causes a beneficial compensating effect. | ||

Revision as of 13:13, 14 July 2011

|

Contents

Introduction

An artificial reef (AR) is a man-made submerged structure whose main goal is to reduce incident waves by inducing wave breaking. However ARs are often constructed as multipurpose structures, i.e. not only to defend the coast from erosion but also to maximise secondary objectives such as to improve spot surfability, to stabilize nourishment material and to create marine parks of increased biodiversity. Since different aims, materials and configurations as well as site dependent factors are to be considered, design criteria for this structures are not easy to be defined a priori.

Materials

Stones

Stones are used especially for rubble mound structures whose hydraulic stability is verified through the formulae available in literature for low-crested structures (Burcharth et al., 2007 [1]).Un-corrected design of the structure (and thus a wrong selection of stone size) causes a low efficiency of the AR. Structure reshaping induced by wave breaking over the reef may occur and produce instability, with stones rolling down from the structure. Stones are relatively cheaper than other materials but can be more dangerous for surfing safety.

Geobags, geotextile sand containers and geotubes

Geotubes consist of sacks made by geotextile that are filled with sand or gravel. They are characterized by a length and diameter of 20 and 3 m respectively and are particularly recommended for deep bottoms (Matteotti et al., 2003[2]). Geotextile sand containers (GSCs) and geobags are very similar to geotubes, although their dimensions are smaller than that ones and thus are usually adopted at lower depths. The cost of a reef made of GSCs is usually greater than in case of other materials because it’s more difficult the placement. GSCs and geobags are often employed as revetments or as seaward slopes of nearshore structures. It has to be highlighted that exhaustive analysis regarding element stability are not available and therefore it is need to combine numerical and physical models with practice and experience in the field to establish the real stability of the GSC.

Reef units

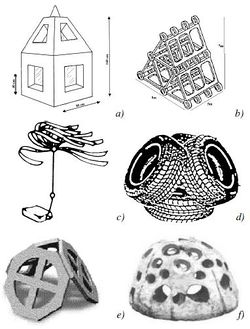

Reef units of different shapes and constructive characteristics can also be used to construct ARs. Particularly in Japan (O’Leary, 2001[3]) these units have a huge popularity and their development is growing. Their macro-roughness induces the dumping of the incident wave agitation above the reef, creating local turbulence and vortices. Usually they are made by steel, reinforced or pre-stressed concrete, fibreglass or a variety of composite materials. These units are produced individually on shore and transported to the staging area. Here they could be combined in a variety of configurations thus allowing adjustment to local conditions and needs. Most of the units are designed to provide nursery areas for fish, to permit a good water recirculation, promote current deflections and marine colonization (O’Leary, 2001[3]). It is very difficult to provide a catalogue of all shapes and materials employed to realize reef units, because the variety of them is huge. Although, some examples are shown in Figure 1.

Figure 1.e shows an interesting sample of reef units, the so-called tecnoreef modules. Constructed from concrete-based natural products, they pose little impact on the ecosystem. Each module consists of reinforced octagonal plates, which are characterized by holes (usually four) having a quarter of a circle shape. The modules are assembled together to create a sort of pyramid that usually consists of

three octagonal plates, the so called “base system”. Generally, the structure basis is always larger than the crest and thus the resistance and stability to cross-shore currents and drag forces are ensured. The modules tend to globally reduce cross-shore currents due to friction and turbulence, with consequent deposition within the pyramids and around them of transported sediments. That is increased by the differently inclined facets on the external and

internal surfaces of the modules. These geometric irregularities act as accelerators for localized microcurrents, and create within each element continuous circular currents (spheres of water) which release their energy upwards. Due to these localized variations, the structure ensures a constant circulation and exchange of water, causing the influx of nutrients and permanent occupation by flora and fauna.

Figure 7.f shows the reef ball elements. These have an hemispherical shape (Harris, 1995) and are typically 1-2 m high and 2 m wide. A reef ball is made by polyester with glass reinforcement and is thus very resistant to corrosion. It’s characterised by high porosity (40-50%), roughness and many cavities or holes:

- that assure a quick colonisations by marine species and aquatic plants (Pilarczyk, 2003a). The increase of structure complexity and consequent increase of induced biodiversity can be improved by roughening the inner and outer surfaces (Pilarczyk, 2003a).

- that generate turbulence and consequently production of vortices and vertical jets; usually, the hole sizes are specifically designed to increase energy dissipation. The reef ball contains a buoy that allows it to float during construction phase and that is deflated when the element is definitively placed. Another important function of the reef ball is to increase the colonization by marine species, i.e. animals and plants (Pilarczyk, 2003a). Under storm attacks, the geometry of reef balls reduces its stability whereas its porosity, through the reduction of lifting forces, causes a beneficial compensating effect.

Geometry

Layout

Cross-section

Dimensions

Function

See also

References

- ↑ Burcharth, H. F., Hawkins, S., Zanuttigh, B., and Lamberti, A., 2007. Environmental Design Guidelines for Low Crested Coastal Defence Structures, Elsevier.

- ↑ Matteotti G., Ruol P., 2003. L’impiego dei geosintetici nelle opere di ingegneria marittima e costiera, 2003 [1]

- ↑ 3.0 3.1 O’Leary, Hubbard T., O’Leary D. Artificial Reefs Feasibility Study, Coastal Resources Centre National University of Ireland Cork, 2001

Please note that others may also have edited the contents of this article.

|